Advanced AI CDMO Solutions Propel Germany’s Pharmaceutical Market with 22.1% CAGR Growth

AI-Integrated CDMO Process Optimization Market set for rapid growth, driving advanced AI adoption in pharmaceutical manufacturing and biotech sectors.

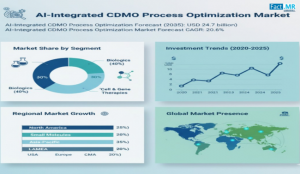

ROCKVILLE, MD, UNITED STATES, October 10, 2025 /EINPresswire.com/ -- The AI-integrated CDMO process optimization industry is poised for a transformative decade, set to redefine pharmaceutical manufacturing and advanced AI-driven process systems. Valued at USD 3.8 billion in 2025, the market is projected to reach USD 24.7 billion by 2035, growing at a remarkable CAGR of 20.6%. This surge reflects the accelerating adoption of machine learning and AI-powered optimization solutions across large pharmaceutical companies, biotech startups, and academic research institutions.During the first half of the decade (2025–2030), the market is expected to grow from USD 3.8 billion to around USD 10.8 billion, adding USD 7.0 billion in value—representing 32% of the total projected growth for the period. This phase will be defined by the accelerated adoption of machine learning and predictive analytics, fueled by rising pharmaceutical digitization and global demand for process optimization. Advanced AI capabilities and digital twin technologies are set to become standard expectations rather than premium features.

Why is the AI-Integrated CDMO Process Optimization Market Expanding?

The market’s growth is driven by three key trends in the pharmaceutical and biotech sectors:

Rising Pharmaceutical Digitization – AI-integrated CDMO process optimization enables immediate process improvements without traditional manufacturing constraints, boosting operational efficiency, reducing costs, and supporting manufacturing excellence.

Manufacturing Modernization Programs – Companies are adopting advanced AI management systems that complement existing infrastructure, providing precise process optimization aligned with efficiency and automation goals.

Pharmaceutical Infrastructure Enhancement – AI solutions help facilities minimize maintenance while maintaining high-quality output during intensive production cycles.

Despite these drivers, market expansion faces challenges. Implementation complexity varies across facility types, and regulatory compliance can limit flexibility in certain environments. Additionally, technical limitations, including AI system capacity and maintenance demands, may increase operational costs in high-volume, quality-sensitive applications.

Drivers, Restraints, and Key Trends in the AI-Integrated CDMO Process Optimization Market

Drivers: Market growth is fueled by pharmaceutical modernization, increasing demand for infrastructure upgrades, and rising global AI technology investments. AI-integrated CDMO solutions enable process optimization without traditional manufacturing limitations, reduce maintenance costs, enhance operational efficiency, and provide flexibility in complex pharmaceutical environments.

Restraints: Growth is challenged by implementation complexity, regulatory requirements, technical performance limits, and compatibility issues across different facility types and infrastructure. High-volume applications with strict quality standards may face increased operational costs.

Trends: Adoption is accelerating in developed markets and expanding into emerging economies. Key trends include enhanced AI capabilities, advanced machine learning integration, and improved maintenance and quality monitoring. Market evolution will focus on optimizing operational efficiency while navigating potential disruptions from alternative AI technologies or regulatory constraints.

AI-Integrated CDMO Process Optimization Market: Key Country Insights

South Korea: Advanced AI-integrated CDMO systems are widely deployed in pharmaceutical and biotech facilities, optimizing manufacturing quality and operational efficiency. Key centers like Seoul, Incheon, and Busan demonstrate premium installations, supporting a projected CAGR of 24.7% through 2035.

Germany: Germany leverages AI and systems integration expertise to optimize pharmaceutical manufacturing. Major hubs including Munich, Frankfurt, and Berlin drive a CAGR of 22.1%, maintaining leadership in Europe with advanced infrastructure and AI management centers.

United States: The U.S. focuses on precision AI systems integrated with comprehensive pharmaceutical platforms, enhancing manufacturing quality, maintenance, and monitoring. Strong biotech demand and modernization initiatives support a 20.8% CAGR through 2035.

Europe: The regional market is projected to grow from USD 1.0 billion in 2025 to USD 6.5 billion by 2035 (CAGR 21.8%). Germany holds the largest share, supported by advanced infrastructure and major AI centers.

Japan: Biologics and biosimilars dominate, capturing 42.8% of AI installations, with a focus on precision AI, operational reliability, and long-term manufacturing excellence. Small molecule APIs account for 28.7%, primarily in specialized applications with advanced AI functionality.

Key Players

Catalent Inc.

Lonza Group Ltd.

Thermo Fisher Scientific Inc.

Samsung Biologics

WuXi Biologics

Boehringer Ingelheim

FUJIFILM Diosynth Biotechnologies

Recipharm AB

Patheon (Thermo Fisher)

Cytiva (Danaher Corporation)

Competitive Landscape

The market is moderately concentrated, with 12–18 key players controlling 40–45% of global share. Competition focuses on AI capabilities, system reliability, and pharmaceutical integration rather than pricing.

Market Leaders – Catalent Inc. (14.8% share), Lonza Group Ltd., and Thermo Fisher Scientific dominate through extensive pharmaceutical expertise, global AI equipment networks, and integrated systems, creating high switching costs and supporting premium pricing.

Technology Challengers – Samsung Biologics, WuXi Biologics, and Boehringer Ingelheim differentiate with specialized AI solutions, rapid development cycles, and innovative deployment interfaces.

Success favors companies combining reliable AI hardware with advanced monitoring software, including quality tracking and automated maintenance alerts. Competition is intensifying as traditional pharmaceutical equipment manufacturers enter AI-integrated CDMO systems, while specialized AI firms target niche applications with cost-effective, innovative platforms.

Browse Full Report - https://www.factmr.com/report/ai-integrated-cdmo-process-optimization-market

Request for Discount - https://www.factmr.com/connectus/sample?flag=S&rep_id=11181

Buy Now at USD 2900 - https://www.factmr.com/checkout/11181

Check out More Related Studies Published by Fact.MR:

Health Information Exchange (HIE) Market:

https://www.factmr.com/report/health-information-exchange-market

Hospital Services Market:

https://www.factmr.com/report/hospital-services-market

Estrogen Replacement Therapy Market:

https://www.factmr.com/report/estrogen-replacement-therapy-market

Arteriovenous Implants Market:

https://www.factmr.com/report/arteriovenous-implants-market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

S. N. Jha

Fact.MR

+ +1 628-251-1583

sales@factmr.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.