Lilac Announces Successful Completion of Lithium Pilot Operations on the Great Salt Lake, Utah

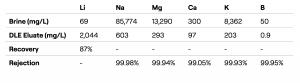

OAKLAND, CA, UNITED STATES, October 7, 2025 /EINPresswire.com/ -- Lilac Solutions, a leading provider of direct lithium extraction (DLE) technology, today announced the successful completion of its lithium extraction pilot operations on Utah’s Great Salt Lake, a key step toward building a commercial facility on the lake. The pilot achieved strong performance results, including 87% average lithium recovery on 69 mg/L lithium brine, exceeding the FEL-3 design basis of 84%. The system delivered 99.97% overall impurity rejection and confirmed Lilac’s ability to economically recover lithium from one of the world’s toughest brines while protecting the lake. The planned commercial facility will produce 5,000 tpa of lithium carbonate equivalent (LCE) in its first phase, doubling current U.S. lithium production.

The pilot marks Lilac’s sixth successful field deployment and demonstrates how technology can bring new domestic lithium supply online from resources once considered uneconomic. Lilac’s technology is designed, engineered, and manufactured in the U.S., making this project an important example of U.S. innovation driving domestic critical minerals production.

The pilot operated for seven months and processed more than one million gallons of brine with a peak flow rate of 15 gallons per minute. The system operated through both winter and summer conditions without the need for brine heating or cooling. Third-party sampling and lab analysis confirmed compliance with all discharge and operator permits, validating Lilac’s non-consumptive and non-contaminating process, which reinjects lithium-depleted brine back into the lake and does not lower lake water levels. Lilac IX eliminates the need for evaporation ponds, requires minimal land, and uses 10x less freshwater than competing DLE technologies.

Key Performance Metrics

• Economic lithium recovery: 87% average, exceeding the FEL-3 design of 84%

• Overall impurity rejection: 99.97%

• Eluate lithium concentration from DLE: 2,044 mg/L (raw eluate, prior to any further downstream concentration or treatment). With subsequent process improvements this was increased to over 4,000 mg/L. Low boron in eluate confirms no boron removal required in the flowsheet

Pilot operations generated data for FEL-3 engineering of the commercial facility and for regulatory applications, including the commercial plant operator certificate, discharge permit, and royalty agreement. Eluate from the pilot plant was used to produce battery-grade lithium carbonate samples for offtakers and downstream technology provider testing. Field operations also provided critical insights for optimizing equipment and operating procedures for the full-scale plant.

With the pilot successfully completed, Lilac is progressing financing, permitting, and commercial offtake agreements for the 5,000 tpa LCE facility. Phase 1 would double current U.S. lithium production, with a future Phase 2 expansion bringing total project capacity to 20,000 tpa LCE. The facility would generate local tax revenues and royalties to support lake preservation, create new jobs in Utah, and become a major new source of domestic lithium supply. First lithium is expected in 2027.

“The success of our Great Salt Lake pilot is a major milestone for Lilac and for U.S. lithium supply,” said Raef Sully, chief executive officer of Lilac. “With our ion exchange DLE technology, we’ve proven the ability to economically recover lithium from one of the most challenging brine resources in the world, while protecting the lake and its ecosystems. This achievement provides the foundation for commercial production that can support America’s domestic lithium supply chain.”

The Great Salt Lake pilot adds to Lilac’s growing track record of projects completed in the U.S., Argentina, and Chile, along with a recently completed pilot in Germany with Neptune Energy.

About Lilac

Lilac delivers modern lithium extraction technology to scale lithium supply for global electrification. Lilac’s ion exchange technology helps customers produce lithium from a wide variety of brine resources with high efficiency, minimal cost, and an ultralow environmental footprint. Lilac is based in Oakland, California. Learn more at lilacsolutions.com.

Elizabeth Pond

VP of Communications & Brand, Lilac Solutions

email us here

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.